Rotating Equipment Consulting

Macek Power & Turbomachinery Engineering offers the equipment purchaser, end-user, or repair shop an experienced, responsive, reasonably priced alternative to the OEM for the resolution of rotating equipment issues. Our knowledge base includes a wide range of elements of design, application, modification, repair, and part manufacturing related to:

- Gas and steam turbines

- Axial and centrifugal compressors

- Mechanical aspects of motors and generators

- Centrifugal pumps

If Macek Power cannot help solve your machinery related problem, then we can probably refer you to someone who can. Contact Macek Power anytime for a quick response to your needs.

RELIABILITY ENGINEER

As the reliability engineer, Macek Power works to maximize machinery performance and up time by evaluating unit historical operating data, reviewing workscopes proposed by repair service providers, and visually monitoring work in progress in repair shops or the field. With more than 30 years experience supervising repair shop and manufacturing work, Macek Power is well positioned to help equipment owners answer the sometimes difficult questions needed to plan maintenance and repair strategies.

APPLICATION ENGINEERING

DESIGN ENGINEERING

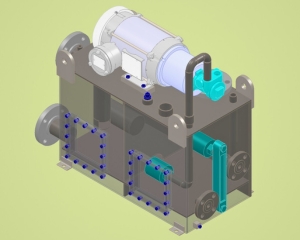

Lube oil consoles and structural steel skid bases for machinery or entire equipment trains for example, are often engineered products. Characteristics such as rigidity, serviceability, operation, and installation method correspond to a need for engineering involvement. Experience, knowledge of applicable standards, and technical acumen make Macek Power an excellent choice for rotating equipment design evaluation or engineering.

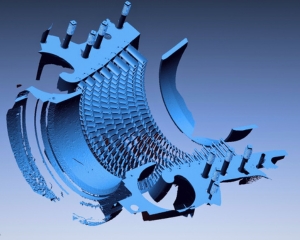

REVERSE ENGINEERING

Macek Power offers extensive reverse engineering experience. This includes geometry acquisition using high precision measuring tools and structured light systems that generate 3D point clouds. Macek Power understands that reverse engineering involves much more than simply “scanning” a part and producing a CAD solid model. The real challenge is determining design intent and understanding which component part features are critical to fit and function, and which are not. Applying the necessary experience to the establishment of design intent not only assures that the newly manufactured component functions as needed, but it also translates to lower manufacturing cost.