Steam Turbine Services

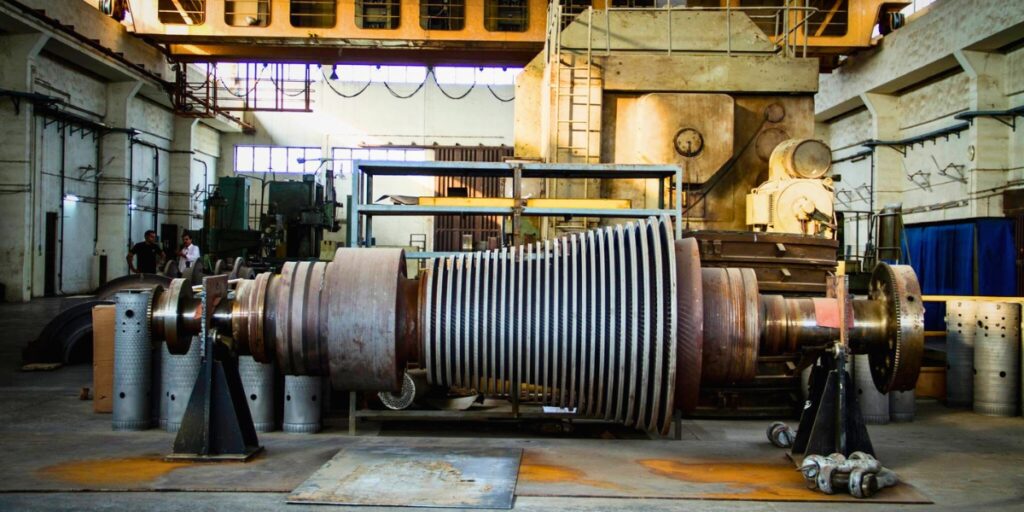

Macek Power is widely known for its steam turbine expertise. We have worked with turbines ranging in size from small single-stage mechanical drives to multi-cylinder utility arrangements rated at more than 500 MW. Services commonly provided include the following.

- Steam turbine re-rates

- Steam path audits

- Component part design and manufacturing engineering

- Installation, commissioning, operations, and outage support

- Root cause failure analysis

STEAM TURBINE RE-RATES

Have steam conditions changed or do you need more power? What about shaft speed? Has it changed? If so, click here to learn more about the Macek Power steam turbine re-rate process.

STEAM PATH AUDITS

Do you want to find lost efficiency during your maintenance outage? Do you know how much lost efficiency is costing you? Click here to learn more about Macek Power steam path audit capabilities.

COMPONENT PART DESIGN AND MANUFACTURING ENGINEERING

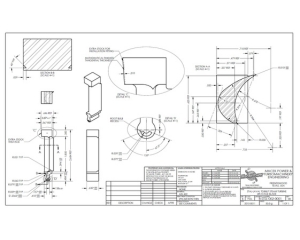

Macek Power designs and redesigns components such as rotor blades, nozzles, diaphragms, seals, bearings, and rotor assemblies to improve operation or eliminate an existing problem. To support these design efforts, we perform thermal and fluid flow calculations, rotordynamic analysis, and structural strength studies as needed. Decades of manufacturing process experience complement our design work, making it possible to serve clients on a turnkey basis with respect to design and subsequent manufacturing.

INSTALLATION, COMMISSIONING, OPERATIONS, AND MAINTENANCE SUPPORT

From the moment the casing is opened to the final machine alignment move, Macek Power provides a wide variety of technical direction related to the mechanical activities that are a part of turbine ownership. Mechanical assembly, instrumentation set point specification, lube and/or control oil system testing, cold and hot commissioning, and shaft alignment are all examples of steam turbine service technical direction routinely provided by Macek Power.

Seemingly small or unnoticed changes in operation can cause significant changes in reliability. Likewise, determining the optimum frequency for minor and major inspections can affect reliability and the cost of maintenance activities. Macek Power advises its customers on the operational aspects of steam turbines, be it on a proactive or retroactive basis. Examples of maintenance-related technical support provided by Macek Power include outage planning, workscope specification, job safety analysis, division of responsibilities determination, and vendor qualification.

ROOT CAUSE FAILURE ANALYSIS

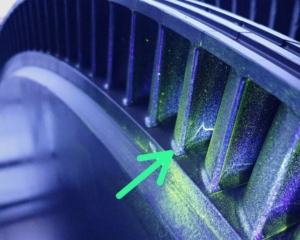

The most commonly failed steam turbine component is the rotor blade. Even when an OEM has more than a century of design and manufacturing experience, failures still occur. Some of the failures are caused by new designs that favor efficiency, energy density, or reduced manufacturing cost over robustness. Other failures can be caused by improper unit operation.

Failure analysis is like detective work. Whatever the root cause, or the component, Macek Power failure analysis procedures include steps such as historical information collection, visual examination, non-destructive and destructive material testing, microscopic and metallographic examination, chemical composition analysis, and failure mode determination. Usually only with information such as this, can root cause be discovered.

Of course, the purpose of the analysis is to prevent recurrence through design or operational changes. Macek Power knowledge and experience, along with its relationships with various laboratories and testing facilities, provide an opportunity for all to learn and improve from the unfortunate failure circumstance.